The rapid growth of the energy storage market has made quality assurance an indispensable part of the production process. According to Google Big Data, over 90% of energy storage battery customers consider safety and long-term reliability their top priorities. These concerns are valid, as improperly tested batteries can lead to performance failures, installation delays, and even hazardous incidents. For energy storage installers and end-users, pre-shipment testing ensures that the product meets rigorous safety, compatibility, and efficiency standards, building confidence in its performance over time.

In this article, we delve into a comprehensive energy storage battery’s 16-point pre-shipment test list, explaining the importance of each test and how it safeguards the interests of both installers and end-users. By examining each point in detail, we aim to highlight the necessity of these tests in delivering a product that performs reliably under all conditions.

Appearance Size and Interface Confirmation

Why It Matters:

Appearance and interface design are the first touchpoints for installers. Misaligned dimensions or defective interfaces can lead to improper installation, which is costly and time-consuming. End-users also expect products that match the advertised specifications for aesthetic and practical reasons.

Testing Details:

- Visual inspection for scratches, dents, or irregularities in the casing.

- Measurement verification to ensure the product aligns with design specifications.

- Testing the robustness of power and communication interfaces to confirm they withstand repeated usage and environmental stresses.

Confirmation of System Parameters

Why It Matters:

System parameters, such as voltage, capacity, and output power, are critical for ensuring the battery works seamlessly with other components. Incorrect parameters can lead to system instability or damage.

Testing Details:

- Cross-referencing rated specifications with real-world output to ensure accuracy.

- Using advanced diagnostic tools to simulate various operational scenarios.

Energy Storage Battery Voltage Sampling Accuracy Test

Why It Matters:

Voltage accuracy is vital for maintaining battery health and optimizing performance. Overcharging or undercharging due to inaccurate readings can prematurely degrade the battery.

Testing Details:

- Utilize calibrated multimeters to validate voltage readings.

- Conduct tests under various load conditions to ensure consistent accuracy.

Energy Storage Battery Current Sampling Accuracy Test

Why It Matters:

Accurate current measurement is essential for monitoring energy flow, preventing overloads, and ensuring proper energy distribution in the system.

Testing Details:

- Compare current readings from the Battery Management System (BMS) with those from calibrated meters.

- Test under varying load conditions to simulate real-world scenarios.

Energy Storage Battery Temperature Sampling Accuracy Test

Why It Matters:

Energy storage batteries operate within strict temperature thresholds to prevent thermal runaway or efficiency loss. Accurate temperature readings ensure safe operation.

Testing Details:

- Use thermocouples and infrared sensors to measure temperature during operation.

- Simulate extreme environmental conditions to test sensor responsiveness and accuracy.

Energy Storage Battery Communication Interface Test

Why It Matters:

Modern energy storage systems rely on seamless communication between the battery, inverters, and energy management systems. Faulty communication interfaces can disrupt system operations.

Testing Details:

- Test data transfer reliability across various protocols, including CAN bus and RS485.

- Assess latency and error rates during simulated operational loads.

Key Circuit Electrical Performance Test

Why It Matters:

The key circuits, including the Battery Management System (BMS), protect the battery from overcharging, over-discharging, and short circuits. Their performance directly impacts the battery’s safety and longevity.

Testing Details:

- Validate circuit integrity under different electrical loads.

- Perform fault simulations to ensure the BMS responds as expected.

EMC Electrical Performance Test

Why It Matters:

Electromagnetic compatibility (EMC) ensures the battery functions effectively in environments with high electromagnetic interference (EMI). Poor EMC can lead to erratic behavior or communication failures.

Testing Details:

- Conduct emission tests to ensure the battery does not interfere with nearby devices.

- Perform immunity tests to check how the battery performs under EMI exposure.

Power Consumption Test

Why It Matters:

Minimizing idle power consumption improves energy efficiency, which is crucial for installers and users who are focused on sustainability and cost savings.

Testing Details:

- Measure power draw during standby and operational modes.

- Verify that consumption meets energy efficiency standards.

Sleep and Wake-Up Test

Why It Matters:

Energy storage batteries must transition smoothly between sleep and wake-up modes to optimize energy usage without causing operational delays.

Testing Details:

- Assess the time taken for the battery to wake up from sleep mode.

- Validate stability of power output during transitions.

Energy Storage Battery SOC (State of Charge) Test

Why It Matters:

SOC indicates the remaining battery charge. An inaccurate SOC can lead to system inefficiencies or unexpected power outages.

Testing Details:

- Simulate varying usage scenarios to ensure SOC algorithms accurately track charge levels.

- Test SOC performance at extremely high and low states of charge.

Energy Storage Battery Key Function Test

Why It Matters:

Critical safety features, such as overcurrent, overvoltage, and thermal protection, must function flawlessly to prevent accidents.

Testing Details:

- Stress-test protective functions under simulated fault conditions.

- Validate the system’s ability to recover from critical errors.

Energy Storage Battery Communication Protocol Test

Why It Matters:

Adherence to standardized communication protocols ensures compatibility with third-party devices, such as inverters and monitoring systems.

Testing Details:

- Validate data integrity when communicating with devices using protocols like Modbus and SunSpec.

Charge and Discharge Temperature Rise Test

Why It Matters:

Temperature rises during charging and discharging impacts the battery’s thermal stability and lifespan.

Testing Details:

- Monitor temperature changes at maximum charge and discharge rates.

- Compare results against safety thresholds to ensure compliance.

Energy Storage Battery Parallel Logic Test

Why It Matters:

In multi-battery installations, parallel logic ensures balanced load sharing and prevents damage to individual units.

Testing Details:

- Simulate parallel operations with multiple batteries to test logic consistency.

Inverter Matching Compatibility Test

Why It Matters:

Batteries must be compatible with leading inverter brands to ensure smooth integration and operation.

Testing Details:

- Test the battery with inverters from top manufacturers to confirm seamless communication and performance.

The Importance of Rigorous Testing

A comprehensive pre-shipment testing process guarantees that every energy storage battery leaving the factory meets the highest standards of quality and reliability. These tests address the critical concerns of both installers and end-users, ensuring that the battery performs as expected in diverse conditions. For installers, this means fewer delays and lower costs, while users benefit from enhanced safety, efficiency, and peace of mind.

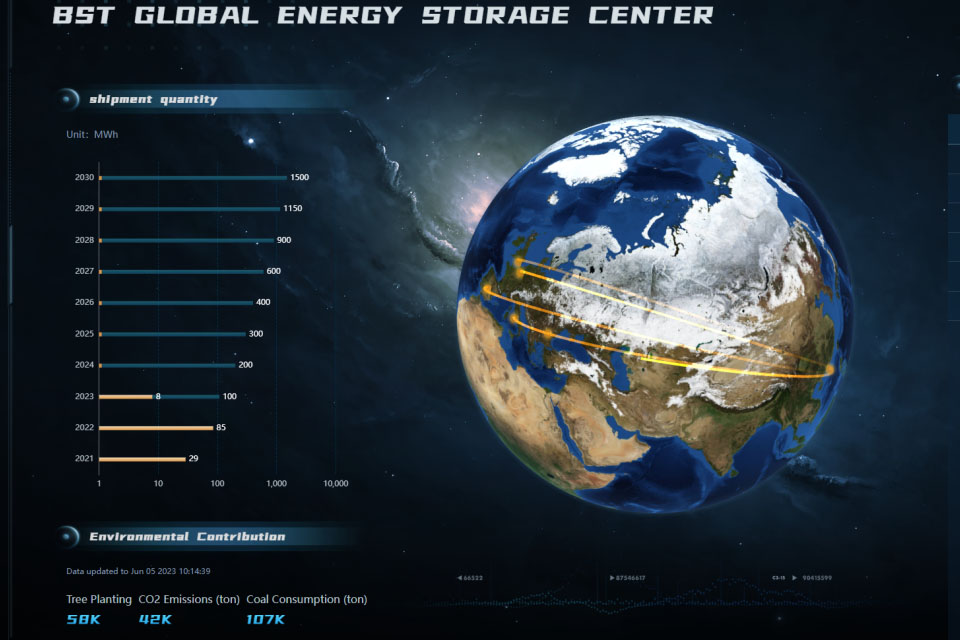

BST: Driving Excellence in Energy Storage

With over 22 years of experience, BST has established itself as a leader in energy storage innovation. Our rigorous testing protocols ensure that every energy storage battery meets global standards for safety and performance. BST continues to pave the way for a sustainable, low-carbon future by investing in cutting-edge technologies and maintaining an unwavering commitment to quality.

By adhering to this 16-point pre-shipment test list, BST not only delivers products that meet customer expectations but also sets a benchmark for the energy storage industry. With BST, you’re not just choosing a battery—you’re choosing reliability, safety, and peace of mind.