Lithium batteries have become the cornerstone of energy storage in the modern era of electrification and sustainability. Lithium batteries power our everyday lives from smartphones and laptops to electric vehicles (EVs) and home energy storage systems (ESS). However, not all lithium batteries are created equal.

When customers inquire about “What type of cells are in lithium batteries?”, they are often referring to two aspects:

- Chemical composition (chemistry) — which determines the performance, safety, cost, and longevity.

- Cell structure (form factor) — which affects the physical design, integration method, and application suitability.

This article explores both in detail, from the perspective of client needs. Whether you’re a procurement manager for an EV company, a homeowner looking for a solar battery, or a buyer sourcing cells for consumer electronics, this guide will help you understand the differences and make an informed decision.

1. Chemical Types of Lithium Battery Cells

Lithium-ion battery technology includes several subtypes based on the materials used in the cathode and anode. Each chemistry offers a distinct performance profile, suited to specific applications. Let’s explore the most widely used types:

1.1 Lithium Iron Phosphate (LiFePO₄ or LFP)

Key Features:

- Nominal voltage: 3.2V per cell

- Energy density: 90–160 Wh/kg

- Cycle life: 3000–6000 cycles

- Operating temperature: –20°C to 60°C

Advantages:

- Exceptional thermal and chemical stability

- Highly resistant to overheating and combustion

- Long cycle life, even under deep charge/discharge

- Lower cost and no cobalt (more ethical and sustainable)

Disadvantages:

- Lower energy density than other lithium chemistries

- Larger and heavier for the same capacity

Typical Applications:

- Home and commercial energy storage

- Solar power systems

- Electric buses, low-speed EVs

- Backup power (UPS)

Customer Case:

A residential energy customer prioritizing fire safety and durability will often choose LFP over higher-density chemistries. For large-scale stationary systems, LFP offers the best cost-performance ratio over time.

1.2 Lithium Nickel Manganese Cobalt Oxide (NMC)

Key Features:

- Nominal voltage: 3.6–3.7V

- Energy density: 150–220 Wh/kg

- Cycle life: 1000–2000 cycles (or more, depending on management)

- Versatile voltage/current combinations

Advantages:

- Excellent energy-to-weight ratio

- Balanced performance: capacity, power output, and safety

- Suitable for high-load applications

Disadvantages:

- More expensive than LFP due to cobalt and nickel content

- Slightly shorter lifespan under harsh cycling

Typical Applications:

- Electric vehicles (Tesla Model 3, BMW i3)

- Portable power stations

- Power tools

- Drones

Customer Case:

An EV manufacturer may choose NMC for its high energy density and long driving range. It enables compact, lightweight battery packs without compromising power.

1.3 Lithium Cobalt Oxide (LCO)

Key Features:

- Nominal voltage: 3.6V

- Energy density: up to 240 Wh/kg

- Cycle life: 500–1000 cycles

Advantages:

- Extremely high energy density

- Lightweight and compact

- Reliable for small electronic devices

Disadvantages:

- Short lifespan

- High cost due to cobalt content

- Low thermal stability and poor abuse tolerance

Typical Applications:

- Smartphones

- Tablets

- Digital cameras

- Portable audio players

Customer Case:

OEM manufacturers of compact consumer electronics often rely on LCO cells for maximum battery life per charge, knowing that end users will replace the product every few years.

1.4 Lithium Manganese Oxide (LMO)

Key Features:

- Nominal voltage: 3.7V

- Energy density: 100–150 Wh/kg

- Cycle life: 300–700 cycles

Advantages:

- Better thermal stability than LCO

- Capable of high current discharge

- Lower internal resistance

Disadvantages:

- Shorter overall life

- Moderate energy density

Typical Applications:

- Power tools

- E-bikes

- Medical devices

- Hybrid EVs

Customer Case:

A cordless tool manufacturer might prefer LMO for its ability to deliver sudden power surges without overheating. Cost-efficiency and safety matter more than long-term cycling.

1.5 Lithium Nickel Cobalt Aluminum Oxide (NCA)

Key Features:

- Nominal voltage: 3.6V

- Energy density: up to 260 Wh/kg

- Cycle life: 1000–2000+ cycles

Advantages:

- Highest energy density among current commercial lithium types

- Long lifespan with proper management

- Low self-discharge

Disadvantages:

- High thermal risk without advanced BMS

- Expensive (especially with aluminum and cobalt)

Typical Applications:

- Tesla EVs (Model S/X with Panasonic 18650 NCA cells)

- Aerospace and defense

- High-performance electric mobility

Customer Case:

A premium EV customer expects longer driving range and powerful acceleration—NCA fits this requirement, but only under strict temperature and voltage control.

1.6 Lithium Titanate (LTO)

Key Features:

- Nominal voltage: 2.4V

- Energy density: 70–100 Wh/kg

- Ultra-fast charging (minutes)

- Cycle life: 10,000–20,000 cycles

Advantages:

- Extremely safe and stable

- Outstanding lifespan (can last 15–20 years)

- Works in extreme temperatures from –30°C to 60°C

Disadvantages:

- Low energy density (bulky)

- Higher cost

Typical Applications:

- Public transportation (electric buses)

- Military equipment

- Fast-charging stations

- Industrial-grade energy storage

Customer Case:

For critical systems such as military-grade robotics or field-deployable charging stations, LTO provides unmatched reliability and performance—even if cost and volume are higher.

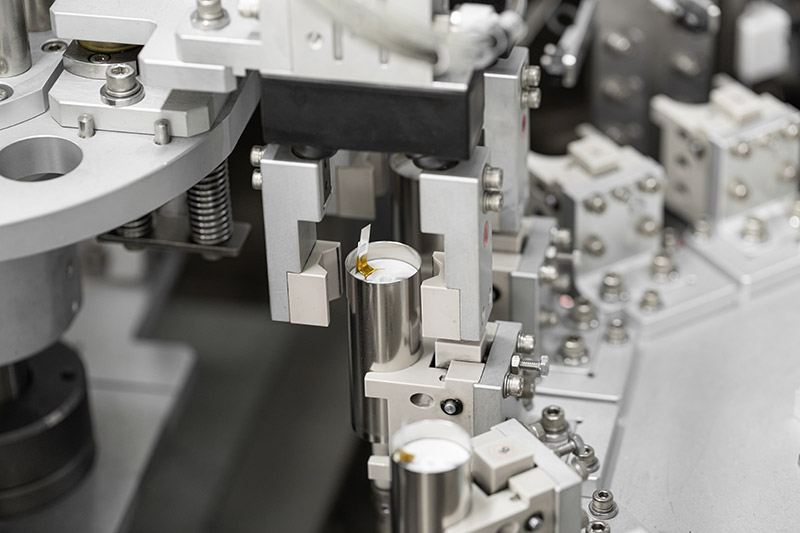

2. Cell Formats: Cylindrical vs. Prismatic vs. Pouch

In addition to chemistry, the physical structure of the cell plays a major role in integration and thermal performance.

| Format | Pros | Cons | Common Use |

|---|---|---|---|

| Cylindrical | Mature tech, good heat dissipation, low cost | Less space-efficient due to round shape | Power tools, EVs, industrial packs |

| Prismatic | Efficient space usage, durable aluminum casing | Less tolerant to swelling, harder to cool | EVs, energy storage systems |

| Pouch | Lightweight, flexible size and shape | Susceptible to swelling, needs protection | Consumer electronics, drones, portable packs |

Note: Cylindrical cells (e.g., 18650, 21700, 26650) are widely used in EVs, whereas prismatic cells are often favored in stationary systems. Pouch cells are ideal for light and compact devices.

3. Summary Table: Comparison of Lithium Battery Types

| Chemistry | Energy Density | Cycle Life | Safety | Cost | Charging Speed | Use Case Examples |

|---|---|---|---|---|---|---|

| LFP | ★★★ | ★★★★★ | ★★★★★ | ★★★ | ★★ | Home ESS, solar storage, buses |

| NMC | ★★★★ | ★★★★ | ★★★★ | ★★ | ★★★★ | EVs, power tools, portable power |

| LCO | ★★★★★ | ★★ | ★★ | ★ | ★★★ | Phones, laptops, cameras |

| LMO | ★★★ | ★★ | ★★★★ | ★★★ | ★★★★ | Tools, e-bikes, medical devices |

| NCA | ★★★★★ | ★★★★ | ★★ | ★ | ★★★★★ | High-end EVs, aerospace |

| LTO | ★★ | ★★★★★★★ | ★★★★★ | ★ | ★★★★★ | Industrial systems, defense, buses |

4. How to Select the Right Lithium Battery Type

Step 1: Define Your Application

- Portable electronics: Choose high energy density (LCO)

- Long-range EVs: Choose NMC or NCA

- Home energy storage: Go with LFP for safety and value

- Heavy-duty machinery or extreme climates: LTO is unbeatable

Step 2: Budget vs. Lifecycle Trade-off

- Higher initial cost (NCA/LTO) ≠ higher total cost if lifespan is long

- Consider cycle life vs. application frequency

Step 3: Prioritize Safety for High-Risk Environments

- Avoid cobalt-heavy types where fire or thermal risk exists

- Use advanced BMS or switch to LFP/LTO

Step 4: Consider Local Regulations and Supply Chain

- Some regions encourage cobalt-free or recyclable materials

- Check supplier certifications (UN38.3, IEC, UL, RoHS, etc.)

5. Future Trends in Lithium Battery Cell Development

- Cobalt-free NMC chemistries (e.g., NMC 532, 811) are gaining traction to reduce cost and ethical concerns.

- Solid-state lithium batteries are being developed for higher safety and energy density, potentially replacing pouch cells in consumer devices.

- Sodium-ion batteries may become a competitor to LFP in stationary storage.

- LFP’s dominance in residential and commercial ESS continues to rise due to its stability and sustainability.

Conclusion

Understanding the types of lithium battery cells—both in terms of chemistry and structure—is essential for making the right purchasing decision. Each type has a unique balance of energy density, safety, cycle life, and cost. Clients should evaluate their priorities, whether that’s maximum runtime, best safety, or longest lifespan.

For businesses, matching the right battery cell to the correct application is not just a technical choice—it’s a strategic one.